Went out back this afternoon to scatter seed for the birds and squirrels, and found a nice autumn scene in a corner of the yard. It's a pretty image as it is, and also a great backdrop for a portrait of an old friend, a 1977 Gibson Les Paul TV Special. We've seen a lot of autumns together since the late '70s, and hopefully there's still a few more yet to come.

Oregon Red Maple and a Kalamazoo Special

Went out back this afternoon to scatter seed for the birds and squirrels, and found a nice autumn scene in a corner of the yard. It's a pretty image as it is, and also a great backdrop for a portrait of an old friend, a 1977 Gibson Les Paul TV Special. We've seen a lot of autumns together since the late '70s, and hopefully there's still a few more yet to come.

Knotty Pine Offset BarnCaster Project, Part 4: Completed Parts-O-Caster

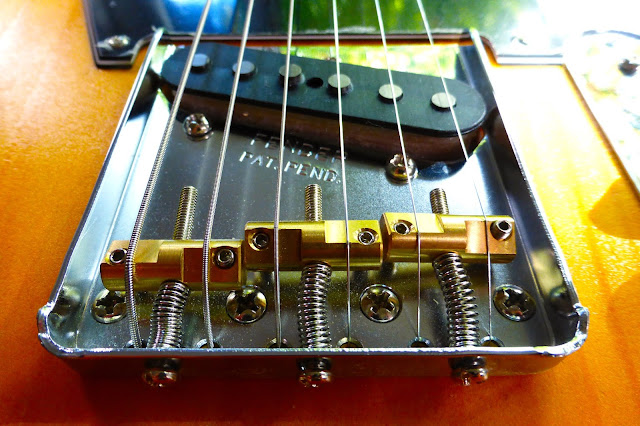

It's been fun putting the knotty pine offset BarnCaster together, and it is now as complete as I envisioned it to be at the beginning of the project. Quirkily attractive, comfortable and well balanced whether on a lap or a strap, plays really well, and sounds astounding, both acoustically and through an amp.

Also really enjoyed playing it throughout the assembly process, but now that it's done, I'm not going to do that anymore. This Parts-O-Caster was always meant to be put up for sale when it was finished, to finance a couple other projects, and I'm certain if I make too much more music with it, I'll fall in love and never want to let it go.

* * *

And... it's sold. To a nice young couple in Nome, Alaska. It's going to be a Winter Solstice holiday present for their beloved lead sled dog, Rupert, and may he enjoy it well. Something about accompanying the team's nightly howling jam sessions.

For more about the Barn-O-Caster, see Part 1, Part 2, and Part 3 in the mini-series about it.

Tube Amp on a Plank # 1: RCA Victor RS-193 Single Ended Stereo Hi-Fi Amplifier

Summer before last, there was a big charity yard sale here in our neighborhood, proceeds of which benefited a local pets help society providing among other things, low-cost veterinary services. During this time in our nation's history when a sizable percentage of the population is morphing into a grievance driven neo-fascist authoritarian cult, rejecting anything related to the common good (and all you soulless gun-clutching lizard people know who you are), I'm thankful that our family lives in an old fashioned American town, now considered "socialist", where helping others still matters. Also parks, swimming pools, libraries, arts and music, summer activities for kids, senior centers, hiking and running trails, post offices, an Amtrak station, and dog play parks!

I helped others (and their pets) out by buying a few things: a pair of new Converse low tops, some Yakima rooftop rack bars, a few interesting books (Keith McCafferty's fly fishing detective murder mysteries), and an early 1960s RCA Victor stereo hi-fi console:

As expected, the musical tone could have been better, but it was okay, and surprisingly quiet and hum free. Next, as a test, I disconnected one side of the speaker-out leads, and hooked that up to a known good sounding speaker, and wow - that was a huge improvement over the stock built in drivers. It was all there - deep tight low end, detailed mids, and shimmery and almost magical sounding highs.

Since, 1) the record changer was basically not totally operational (and I wouldn't have trusted it with some of our vintage LPs anyway), 2) the console's speakers weren't exactly audiophile quality, and 3) as furniture, the console cabinet had seen better days, the next step was obvious. Rescuing the really great sounding tube stereo amp section and re-purposing it sounded like a fun project.

The amplifier was removed, and the console cabinet, with turntable, was sold on craigslist (really cheap) to someone looking for a vintage piece of furniture to refinish and use for storage - the full width hinged top lid was a great feature for that purpose.

Here's a quick rundown of the amp's basics:

- There are two high level (near line level) inputs into a dual section 6EU7 voltage amplifier / output driver tube, with its plates driving the input grids of a pair of 6BQ5 (EL84) output tubes

- Estimated output power: 3 to 5 watts per channel

- Controls consist of a dual section loudness potentiometer, dual passive bass and treble (also dual section) controls, and a balance pot

- 5Y3 rectifier tube

- Two separate output transformers

The next picture shows the amp innards, after I'd done a few minor changes:

In the above photo, note the flat brown "blob" in the upper left corner - that's a separate component board, encased in some sort of soft mastic-y material, that holds the loudness control sub-circuit. That's one of the keys to this amplifier's sound; not only a volume level control, the loudness circuit also has a variable level Fletcher-Munson EQ compensation, subtly boosting the lows and highs at lower volume settings.

A short list of the non-invasive "mods" performed on the amp:

- Added a power on/off switch (originally done at the turntable's "play" knob)

- Added an easy to access fuse holder

- Installed a larger gauge 3-conductor grounded AC cable, with strain relief

- Lifted one leg of the 6.3VAC tube heater loop from ground, and installed 2x 100 ohm resistors referencing both heater legs to chassis ground

- Removed the original hard wired audio input terminals, and replaced with a pair of standard RCA jacks

- Installed a low light-level LED power status lamp, hooked up to one leg of the heater supply; the added terminal strip at the bottom of picture just right of center, shows the voltage dropping resistor and IN4007 diode

- In place of the original control knobs, which had shafts long enough to reach through the 3/4" cabinet panel, four vintage made in Chicago Dakaware Davies style knobs were fitted

At some point in the past, some professionally done servicing had been done to the amplifier - note the pair of large orange .047uF Sprague coupling capacitors, and a replaced 220K plate load resistor. Nice to know this old stereo had been loved enough to be well taken care of.

A great part of doing this project is that since it was in fantastic shape and sounded good as is, no major repairs or circuit changes had to be done; in fact, the audio pathway in this tube amp is all original and unmodified. Also, no additional holes had to be drilled in the chassis, although some had to be enlarged to accommodate added parts, such as the fuse holder and power switch.

Here's a view of the back of the amp. The General Instruments multi-section can style capacitor is still in excellent condition after all these years - not even a bit of audible hum. The output transformers were made by Midwest Coil And Transformer, in January of 1962:

A top shot. Note the AC cable, stolen from an Apple MacBook Pro power supply:

The amplifier chassis was mounted on a piece of rustic finished old growth Oregon alder board, reclaimed from a house being remodeled in Eugene Oregon, originally built in 1964. This board, previously a part of a utility room shelf, had no finish on it. After cutting it to length, a light sanding got it down to clean wood, and two coats of amber shellac were applied, with a steel wool rub down between coats. The last step was polishing with a rag cut from an old favorite cotton flannel shirt.

The RCA Victor logo badge, with the classic style "His Master's Voice" dog and wind-up Victrola, was originally on the front of the console that this amp was removed from. The badge, made of plastic, has two round pins on its back, which fit into two holes I drilled into the front edge of the plank:

The black rubber feet are from an early 1960s McGohan tube paging amp, which received much larger new rubber feet.

Here's a picture of the nicely muted LED power indicator lamp in action:

The LED indicator lamp is a redundant feature - the four vacuum tubes are themselves a sure way to tell if this amp is on. But it was fun to install, and there was already a hole in that spot, so why not? At first, I put in a neon lamp, but yow - that was noisy; the LED is dead quiet.

One end of the chassis has the new RCA style audio input jacks. I had only black and red old fashioned Dymo label stock on hand, but they corresponded nicely with a vintage Switchcraft double-RCA cable with red and black coded plugs:

I like Dymo punch style labels, they're incredibly retro and vintagey looking, and certainly are era specific for this 1960s amp.

A shot of the other end of the chassis:

Close up - here you can see the bat lever of the miniature DPDT AC switch, the AC cable w/ strain relief, and new old stock fuse holder. Also, a good picture of the slot head brass wood screws and stainless trim washers I was lucky enough to find at our local "home town" True Value hardware store, only 10 blocks away:

The power transformer, made by the Foster Transformer company, also in January 1962:

Another front view of the amp. The RCA 5Y3 rectifier and RCA 6EU7 driver tube are likely original. The General Electric 6BQ5 output tubes might be original equipment, or possibly replaced when the amp was serviced a few years ago. Note also the interesting speaker output terminals; I had to fabricate a pair of dedicated speaker cables, with two "+" fittings, and only one "-" fitting.

Here's the back side again:

In its original location in the console, the amp's knobs were pointing up, and the tubes and power transformer were sideways. The pins on the vacuum tubes are probably a lot happier now. Actually, since the rescue and re-purpose, this old tube amplifier seems to sound happier overall.

Using an adapter cable, an iPhone was hooked up, with great results. In this picture, you can see the amp end of the speaker cable assembly:

The RCA RS-193 has been hooked up to a few different pairs of vintage speakers; here are three of them, with an Onkyo DX-1800 compact disc player as an audio source. First, a pair of late '70s JBL L19:

A pair of 1950s James B Lansing D123 12" full range in JBL cabinets, no tweeters:

Sure, both sets of JBls sounded as awesome as they always do with almost any amplifier, but the most relatively astounding match up was with a pair of 1980s Radio Shack Minimus 7 mini speaks. I could go on about how honest and realistic everything sounded with this system, but you might not believe that a 3 to 5 watt per channel amplifier and tiny speakers could reproduce music so well. Guess what? They do.

The Circuit

Without going into a lengthy full analysis of the RS-193's circuit, a few key points are:

• The bass and treble controls are passive instead of active; that is, they are subtractive in their action, cut only, and since they don't boost bass and treble at their respective knee frequencies, it eliminates the possibility of any unwanted resonant peaks in the overall frequency response.

• Rather than "volume", there is a "loudness" control. Each channel's loudness potentiometer (1/2 of a double ganged 500K pot) is multi-tapped and connected to a sub-circuit between the driver amp and power output stages, which enables a variable EQ compensation effect (ie: Fletcher Munson curve) dependent upon the overall volume level.

• At roughly 56mA of plate current at idle through each of the 6BQ5/EL84 output tubes, this amp is firmly in Class A territory.

• With an 80uF electrolytic capacitor on the DC leg of the 5Y3 rectifier tube, the RS-193 has two to four times the primary B+ filter capacitance of most tube amplifiers with similar plate voltages, which helps to reduce hum and noise.

• Instead of two single-ended output transformers, each 6BQ5/EL84 is connected to the primaries of its own double-ended output transformer. The B+ voltage from the power supply is hooked up to the center tap, one primary leg is connected directly to the 6BQ5 plate, and the other leg, which acts as an additional filter choke, goes to the screen grid of each 6BQ5, through a dropping resistor (and also provides voltage to the plates of the 6EU7 driver tubes). This ingenious use of two double-primary output transformers, with their added AC ripple filtering, helps to keep the amplifier's noise floor down - a good thing in general, especially since single ended tube amps tend to have a bit more inherent noise than push-pull circuits.

All in all, a deceptively simple yet sophisticated, efficient, and tonally superior tube amplifier circuit design. This amp came along at the very end of the first tube audio era, just before transistors took over, and may well be the very last tube amplifier RCA ever designed and manufactured.

Click or tap on any photo above to see larger, higher def images. All photographs taken with a Lumix ZS25 pocket travel zoom camera.

Installing a Rustic Plywood Plank Floor

This has to be said, even though it's an uncomfortable truth: wall to wall carpet is disgusting, unsanitary stuff. No amount of shampooing and vacuuming will ever get it clean, especially when living with kids and pets.

When it was time to coat over the also awful (but not unhealthy) offwhite / eggshell walls with brilliant pure white semi-gloss paint, it seemed like a good idea to finally replace the old carpet with something else - anything really, we hadn't decided yet, but not more carpet. In the next picture, during the repainting, the icky pile had already been taken up from half the living room and tossed.

We put up with the dirt and germ catching floor covering that came with this place for way too long, but other money-magnet things always needed doing instead. It was an incredibly joyous event when it all went out the door. If we'd waited two or thee more years, it would have grown legs and walked out by itself.

When we did this a couple years ago, there wasn't much interest in cut plywood floors then. If you google "plywood plank floor" now, you'll find tons of info.

By the time we'd gotten the floor down to a swept and vacuumed, staple and nail free particle sub flooring, without rusty and dangerous carpet tack strips (big job in itself), we had decided on the idea of ripped plywood planking, and got started right away. We went to Mike's Discount Lumber in north Eugene and picked up 7 sheets of 1/2" A-C sanded-top fir plywood, and some 2x4s. Also stopped at Jerry's Home Improvement and got a Kreg Rip-Cut saw attachment and a new carbide tipped blade for the vintage 1980s USA Black And Decker.

On the side deck, which also needs replacing or sanding and staining, an impromptu ripping jig was set up with the new 2x4s, basically cut in half and screwed down to the deck boards:

It took a few minutes to figure out how to attach the Rip-Cut to the saw, and set the rip width. I settled on 8" cuts, for a real "plank-y" look, like what thick solid wood floors in old warehouses and grain mills look like. Due to the width of the blade cuts, this made five 8" planks, and one 7 3/8" plank from each sheet of plywood. Three narrower rows of planks were interspersed through the room, and aren't very noticeable.

Each sheet was held onto the jig by a really simple method. A 1 1/2" wood screw was driven down into the 2x4 right at the edge of the sheet, with the counter-sunk head of the screw about half way down the thickness of the sheet. Then, a moderate tap of the hammer on the opposite side of the sheet dug the plywood into the head of the exposed screw, gripping it well enough so the sheet didn't move while running the saw+Rip-Cut assembly down the length of the plywood. See below at the front left corner, near a made in Switzerland Bosch drill-driver:

After a plank was ripped from the sheet, the remaining plywood was moved over to the edge of the jig, and the securing screw was moved to its new location next to the sheet.

The saw blade was set for about a 5/8" cut depth, and down the sheet we went - really slick and very accurate cuts, every time. It's best to not stop during the length of the cut, just one long sweep at a constant rate of travel. It really helps to have a brand new, super sharp blade, too.

Here's a picture of the very end of a long rip. In this case, we're doing a much narrower cut, essentially re-ripping previously cut planks, to fit the space between the next to last row of planks, and the "far" wall - more on that later. I was on the deck to take this photo, but I always stood to the left of the saw while walking it down the plywood.

After ripping each plank, it was put on a pair of sawhorses, and sawdust was brushed off. We piled up two sheets worth of planks - 12 - here at a time, before going to the edge sanding stage.

While on the horses, any thin un-sawn bits were removed with a new blade in a Stanley knife.

Note the totally weird fake fireplace in the photo above. Not 100% phony - it's got ceramic faux logs with gas burner jets, and an electric ignition switch on the wall. We covered it up with a piece of paneling, painted that gloss white, and put the piano in front of it.

Below is the only picture I took of the big 10" cut off saw that friend John loaned us. It was used to - guess what? - cut off the planks into shorter lengths, as needed to create a random appearing plank laying arrangement. Even though I put a brand new fine tooth blade on it, the first cut was jagged and splintery - very discouraging.

I remembered about putting masking tape on the tops and bottoms of the tuner holes in guitar headstocks, prior to reaming them out to a larger bore to fit cast tuning machines, to avoid splintering the finish. So we tried making a cut with tape over the penciled in cut lines, and hooray - that also worked on plywood planks:

After each length cut, I did rounded edge sanding on the ends of the planklets.

One great reason for doing projects like this is getting to use tools that you normally wouldn't - I'd never handled a cut off saw or a pneumatic nail gun, and it was fun learning new skills.

We were going to rent those tools, but friend, expert tool guru, and all around nice guy John insisted on loaning them to us, and was on hand for some quick and deep instruction. He actually laid the first row of planks, describing each step and tossing in helpful tips. Plywood planks were a new concept for him too, but he'd had a lot of experience with other materials.

This a good time to describe this room, which has an unusual layout: basically 17' square, there's a quasi-hallway running down one side of it from the front door and stairway, back to the kitchen and rest of the bottom floor. This semi hallway is separated from the rest of the room by a strange 1/2 height wall, with a 6' wide doorway/opening in the middle, leaving a 13' wide by 17' long livable space.

The first plank was placed in front of the "doorway" to the room, and centered in the opening. Then, two other planks were cut down to fit on either side. Each plank got a good squirm of builder's adhesive on its bottom side, then laid down and nailed in place. Starting with the second row, a 16 oz hammer knocking against a short piece of 2x4 was used to bend the plank sideways to ensure as tight a fit as possible against the previous row - then, stepping on the new plank to hold it in place, pin nails were shot to secure it.

In the picture above, you can see the still-okay '80s vinyl tiles covering the "hallway" part of the room. There was an evil looking trim plate covering the transition between the tiles and the carpet - that was tossed. After the planks were laid, a 4 1/2" wide piece of hemlock moulding with one radiused edge became the new transition plate, covering the jagged edge of the tiles nicely. Also note the stains on the particle board sub-floor; part of our philosophy here is clean and sanitary new materials and paint totally covering up old sins.

Below, there's already six rows of planks laid, with the 7th row started. I would talk about the process of randomizing the plank pattern, but I actually shut off my mind for this step of the installation. Doing a balancing act between esthetics and the need to minimize cutting to avoid having too many short pieces toward the end of the project, I sort of entered a zen like mental space. It was like one long improvisational guitar solo, with the only contact with real time being the interface with the tools, doing steps in order, and working safely. Having a couple extra sheets of plywood would have ensured having fewer left over small pieces, but it was more fun this way.

Also fun was, toward the end of the plank laying, bringing in some furniture and having a place to relax and scope out the scene. Notice the white painted piece of paneling I'd mentioned earlier, that eventually covered the fake-o fireplace.

A 10 oz trim hammer was used periodically to drive any pin nails that didn't get down at least flush with the plank tops. Pins that haven't been driven deep enough can be found by running your hand lightly along the plank surfaces.

Same exact time, a view in the other direction. We're almost out of planks at this point. And yes, we have an old fashioned land line telephone - the wireless signal here in the South Hills can be bad sometimes.

Next photo - here's some left overs from intentionally cutting out the "footballs" (wood knot covering plugs) from the planks. Highest quality A - C grade plywood has few to none of these plugs on the top surface, but the stuff we got from the discount lumber place had a bit more. Luckily we had enough planks clear of footballs to get the job done.

You can also see in this picture how tightly we were able to get the planks to fit together - a testimony to the accuracy of the Kreg Rip-Cut and new blade on a high quality vintage saw, and also a great edge sanding job by The Kid:

The only ply plank floor I'd ever seen was at a fixed up old farmhouse south of Creswell, Oregon. The owner had ripped 3/4" coastal Douglas fir plywood planks, and laid them down without bothering to round off the edges or getting a tight fit - there were a lot of gaps, really rustic. Then, he had painted the whole floor high gloss white, and the end result was beautiful; it was hard to get my satellite TV repair service call done, I kept looking at that wonderful floor.

We considered painting our own plywood floor, but settled on using plain old fashioned clear shellac. Totally natural, non-toxic, and dries really fast - all important attributes for us, and we also needed to get back into the living room quickly, since rain was in the extended weather forecast.

Here's a picture below showing the difference in coloring between a row of planks already shellacked, and bare uncoated wood. Even though the shellac we used was clear and not the unfiltered amber variety, it really knocked down the naturally pink cast of the western red fir plywood:

All three of us here shared the shellacking process, and we got each coat done fairly quickly.

The floor after one coat of shellac:

Another view:

Here it is with two coats of shellac:

The plan was to have at least three coats of shellac, preferably four, but time was running out due to the weather changing. Two turned out to be enough, since most of the traffic areas are covered with wool rugs.

Sometime during the flooring job, a total eclipse of the sun occurred. Here's a picture of how the sunlight looked on a plywood plank, filtered through the leaves of an oak tree while the eclipse was happening:

After giving the shellac three days to dry, we put on trim moulding around the walls, on top of the plywood flooring. This is pine trim stock; it's usually painted, but its varied color fits in nice and unrefined with the rustic floor.

Note the light in this photo - the sky was full of dark and swiftly moving clouds. Rain was coming in, and I was working fast to get all the outside steps done before it hit. I didn't stop and take any pictures of the moulding installation, and it was well after dark when the last trim nail was in place.

Not too late to take a well deserved break, open up a beer, and set up a place to sit and soak up the new atmosphere and ambience, while listening to the rain on the high ceilinged roof.

In total, after purchasing the paint for the walls and some brushes and new rollers, seven sheets of plywood and a couple 2x4s, nine 8' strips of pine moulding, some hand tools, the Rip-Cut attachment and new blades for both saws, some clips of pin nails and a few tubes of adhesive, 2 1/2 gallons of shellac, well earned pay for The Kid and a quantity of micro-brews for John, we spent a bit more than $600 on our living room renewal project. We could have saved a bit here and there, but that's still a whole lot less than it would have cost with almost any other sort of flooring.

A couple weeks later, we got two very hand-made-ish looking low pile wool rugs, one 8' x 10', and another 5' x 8', to suit various room arrangements. To get some sense of scale here, the 1963 Flexsteel sofa below is 7' long.

We installed a long curtain rod along the front window wall, and put four panels of semi sheer white gauzy looking curtains on it.

After a month passed, the new plywood plank floor didn't seem new anymore. Three months on, we had forgotten the old carpet ever existed, and having a nice, fresh and sanitary living room felt normal.

On Christmas Eve day it snowed. Unusually for this part of Oregon, Christmas morning was sunny, with lots of light coming in reflecting off half a foot of new snowfall outside, and we had a happy, bright, and cheerful holiday.

Peavey Pacer Tube Amp Conversion Project, Part 2

In Part 1 of the Peavey Pacer Tube Amp Conversion Project, we bought a really cheap Pacer, which the seller admitted didn't work very well. The main goal at the time was to rescue the very nice sounding Eminence / Carvin British Series 12" speaker that was in it. Here's how the Pacer looked when it first came home:

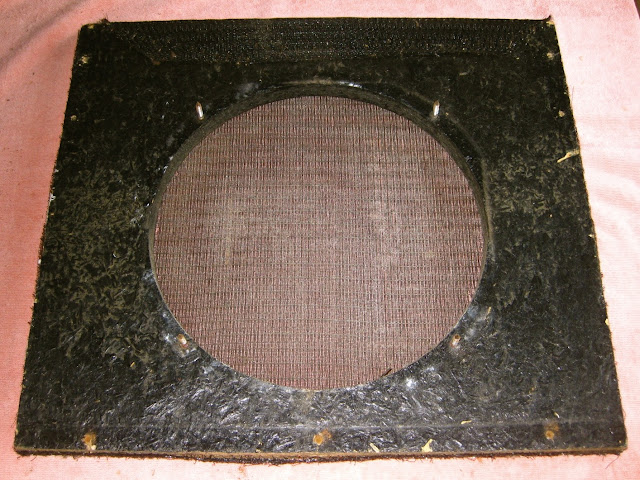

The Pacer's amp section was eventually successfully repaired. However, while it was busted, I decided to salvage the excellent quality light weight jointed pine cabinet, and turn the chassis into a simple tube amp. So even though it now worked well, it was still taken apart, and the working - and very much alive and loud - circuit components were sold, and the horrible looking and super heavy baffle board was given to a junk-loving neighbor:

Before it was cut smaller, I should have taken a photo of the replacement baffle, which came from an ancient (and dead) electronic organ. It was so old that the speaker cutout hole was larger than any made in the last 60 years at least, but luckily the mounting screw + T-nut diameter was almost the right size. After trimming the board to fit the Pacer cab, I shortened the left over pieces, to make a "rattle strip" frame on the front of the baffle, which was glued and stapled to the baffle:

Not shown is another smaller piece of leftover plywood attached at the upper left of the baffle to hold a logo badge.

Here's a picture of how much the new modern, larger T-nuts hung over the organ speaker baffle cutout - only three out of four tines took a grip into the plywood:

That old plywood is amazing - void free fir plies, extremely light weight and almost zero flex. Nobody makes plywood like that anymore:

A new machine screw + washer, one of four holding the speaker down onto the baffle:

This particular 12" speaker is a much used and well loved early '70s Altec Lansing 417-8C, re-coned badly by a place I won't mention:

When I first got the Altec, it was new, minty, not a scratch on it. If you ever wondered why many older guitar amp speakers are beat to sh*t, it's from heavy gigging during the waning days of the now bygone saloon and roadhouse era.

Often one-nighters, when the show was over the cables would get rolled up and shoved into the bottom of the amp, whatever effects pedals were also thrown in there, along with a beat up Unidyne 545 (later an SM57) vocal mic, and the amp (either a 1965 Fender Pro Reverb or a '64 Deluxe Reverb) would get humped out to the parking lot and tossed into the trunk. The wear on this Altec is from about 450- 500 gigs over a 5 year period:

My guitars looked almost as bad.

Here's what the magnet structure of an Altec 417 looks like under the sheet metal cover. What you see isn't the super powerful Alnico magnet, it's an iron basket surrounding the magnet and concentrates the magnetic field for higher efficiency, according to some scientific principles I don't pretend to know. "I only drive these race cars, ma'am, I don't design 'em!" (quote from A.J. Foyt):

Note the old blue Arrow stapler in the above picture - that's going to get used when the grill cloth gets attached to the baffle.

Here's the beautiful grill fabric, unrolled right after getting it in the mail from friend David in Massachusetts. This material also came from an ancient organ, but still in really nice shape:

I put that cloth under a heavy rug for about a week, and most but not all the kinky bends in the fabric settled down.

Sorry, didn't take photos of the grill cloth attachment process, which was an hour and a half sweaty wrestling contest between me, the material, the baffle, and the staple gun. After three long rounds, I finally won the match.

Check out the really ugly glue residue left behind after the original front control panel plate was removed:

Actually, I kept getting dissatisfied with the way the weave didn't want to lay straight, so the staples were pulled, and we started 'rasslin again. In the next picture, you can see a few of those staples. After getting the cloth on as straight and as tight as possible, a metal straightedge was placed on the back of the baffle, and the cloth was neatly trimmed with a new blade in a Stanley knife.

I was going to paint the baffle black prior to putting the cloth on, like most other guitar amp speaker boards, but the grill material looked best in front of the natural golden color of old fir. Note the "semi- floating" baffle attachment to the three cleats on the cabinet sides:

Here's a close up of a machine screw holding the Carvin/Eminence to the baffle, and a wood screw attaching the board to the cleats:

A still life portrait, with guitar, home brew amp and overdrive pedal, and ex-Pacer cab:

This upside down picture shows a possible component layout. The power transformer (also old ex organ amp), with 660VAC no-load on the secondaries, used to power 4x 6K6 output tubes, as well as 3x 6SN7 preamps + inverter and a 5U4 rectifier. It should (hope!) provide enough current to do a cathode biased 20 - 25W push pull 6L6GC circuit:

Penciling in the location of the tube sockets. It shouldn't be too hard to drill out their holes with a step bit, since the chassis is aluminum. The mounting holes for the power transformer will be reinforced with steel straps inside the lightweight metal chassis.

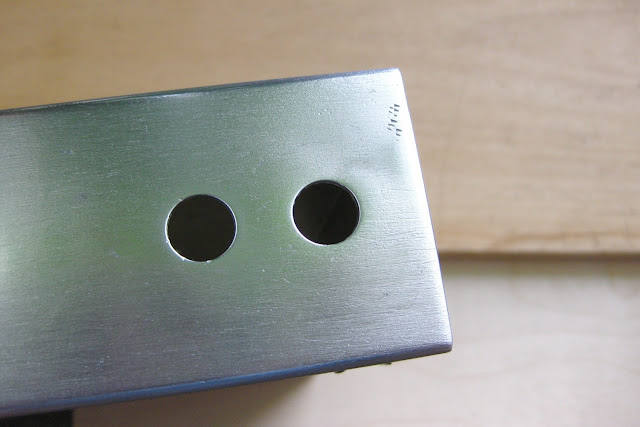

The awful dried up glue on the chassis front was bugging me, but removing it was a chore. 97% alcohol didn't faze it, and neither did GooGone or GoofOff or whatever that household solvent is. In the end, the job needed 3 grades of sandpaper, followed with steel wool, always sanding and scrubbing in the same longitudinal direction:

One end of the front of the chassis had gotten whanged in the past; some aggressive sanding made the ding almost gone. Hopefully whatever paint we end up using on the control panel will cover the remnants:

Removing the dried up zombie adhesive took a lot of time and effort - because of that, the rear panel plate will stay on, as is.

A view down at the power indicator lamp end of the front panel:

This last picture shows a possible control layout mock up. From left to right: two input jacks, volume, treble, middle, bass, presence, two as-yet unknown switches or controls (or maybe just nickle plated sheet metal plugs), and power-on lamp. Those vintage Davies maroon knobs go well with the color of the grill fabric:

The Saab logo thing, which fell off a 1975 Saab 99 Combi Coupe I used to have, is either a joke, or maybe a keeper.

Okay, that's all folks, until next time, when we start drilling attachment holes in the chassis for the transformers and tube sockets.

For the beginning of this project, see Part 1.

Click or tap on any photo above for larger, higher def images.